- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

English

Views: 247 Author: Hong Publish Time: 2023-08-14 Origin: tfwvalve

Find out the most suitable valve type for your industrial requirements and guarantee peak performance with routine maintenance.

Butterfly valve can be opened and closed quickly by rotating only 90°, easy to operate, and at the same time the valve has good fluid control characteristics. When the butterfly valve is in the fully open position, the thickness of the butterfly plate is the only resistance when the medium flows through the valve body, so the pressure drop generated by the valve is very small, so it has good flow control characteristics. Butterfly valve has elastic soft seal and metal seal two sealing type. Resilient soft seal valve, the seal can be set in the valve body or attached to the butterfly plate around.

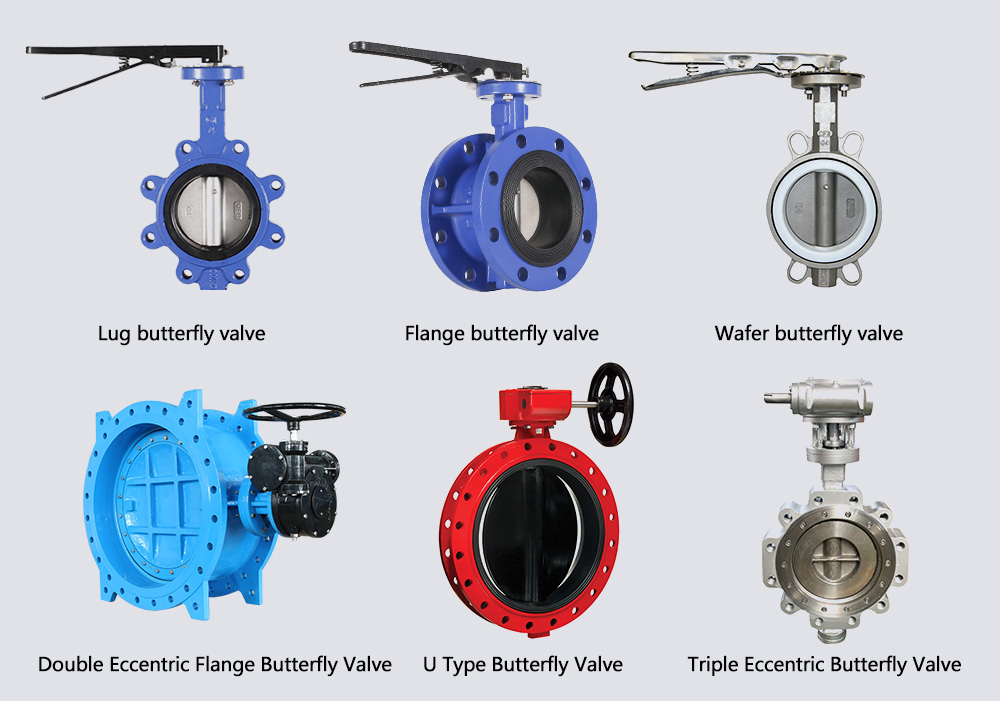

Centre line butterfly valve

Single eccentric butterfly valve

Double eccentric butterfly valve

Triple eccentric butterfly valve

Soft seal butterfly valve

Seal valve seat non-metallic soft material to non-metallic soft material composition.

Seal valve seat metal hard material to non-metallic soft material composition.

Metal hard seal butterfly valve

Seal vice by metal hard material to metal hard material composition.

Vacuum butterfly valve working pressure is lower than the standard atmospheric pressure butterfly valve

Low-pressure butterfly valve nominal pressure PN <1.6MPa butterfly valve

Medium-pressure butterfly valve nominal pressure PN 2.5 - 6.4MPa butterfly valve

High-pressure butterfly valve nominal pressure PN 10.0 - 80.0MPa butterfly valve

Ultra-high pressure butterfly valve nominal pressure PN> 100MPa butterfly valve

High-temperature butterfly valve t>450 ℃ butterfly valve

Medium temperature butterfly valve 120 ℃

Room temperature butterfly valve 40 ℃

Low-temperature butterfly valve 100 ℃

Ultra-low temperature butterfly valve t < 100 ℃ butterfly valve.

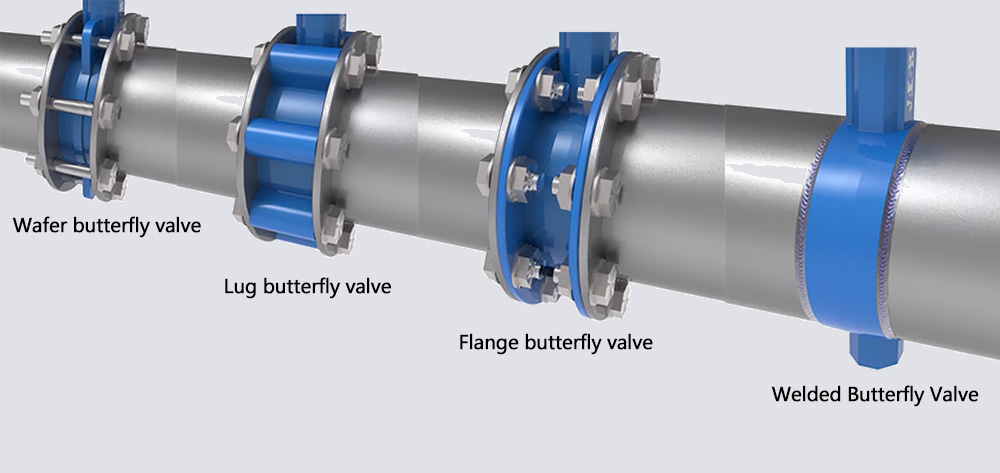

Flange Butterfly Valve: valve body with flange, and pipeline using flange connection

Lug butterfly valve: valve body with internal or external threads, and the pipeline using threaded connections

Clamp Butterfly Valve: Clamp hoop connection valve: the valve body with a clamp port, and the pipeline using the clamp hoop connection

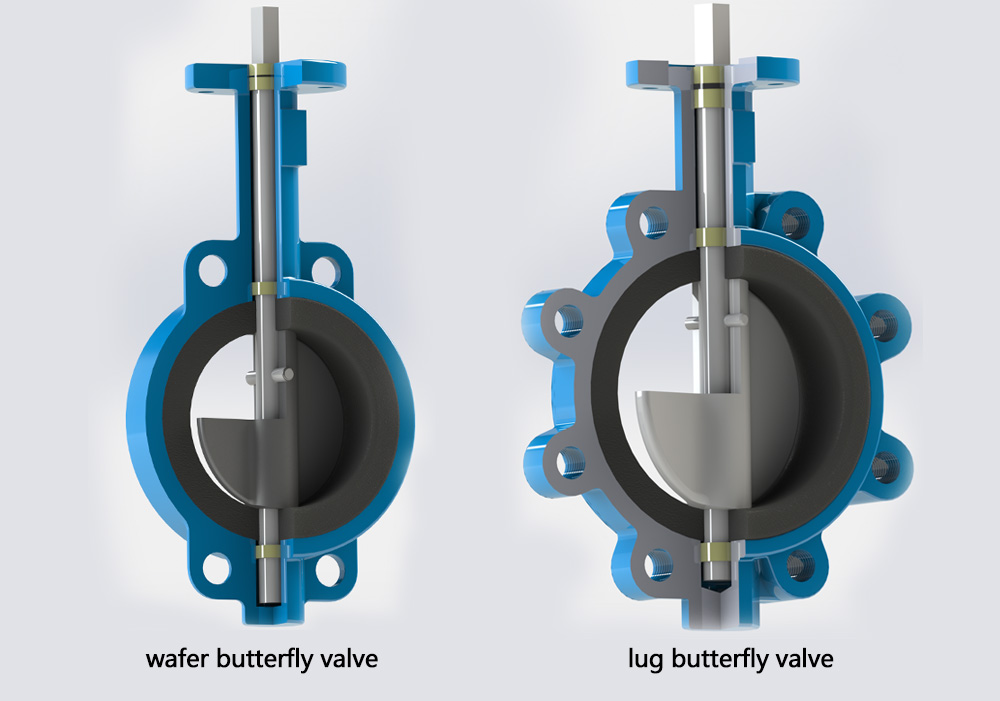

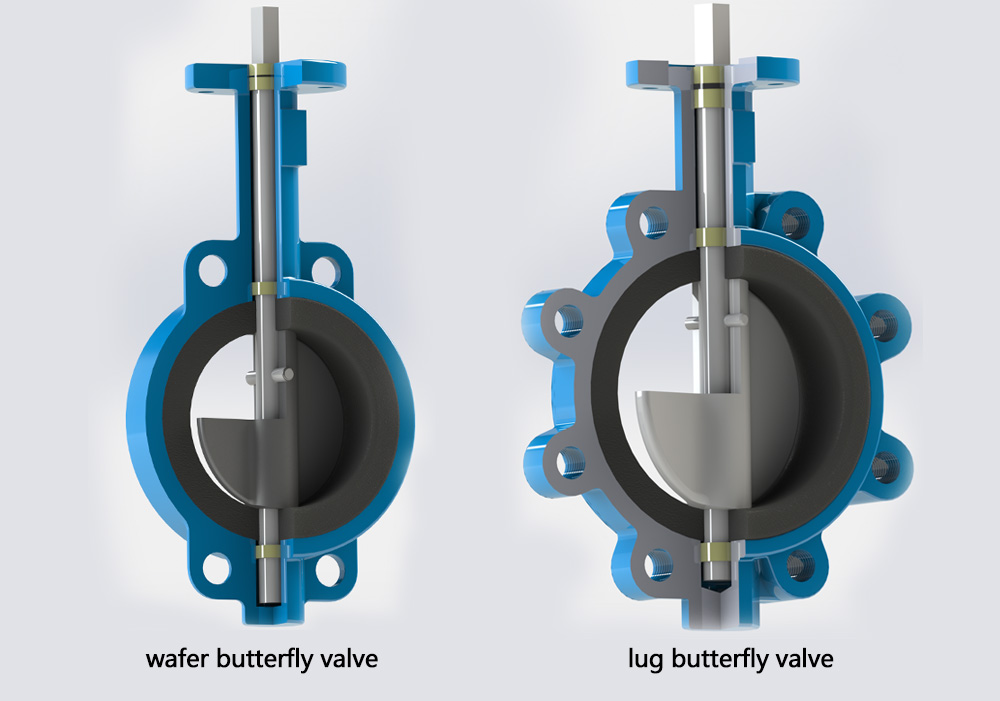

Conventional wafer type butterfly valves have either four holes or two holes. Alignment holes that match the connecting pipework. These valves are used to clamp between two flanges of a pipework system. This design meets most flange standards for easy installation. The valve seats are made of EPDM or NBR, or PTFE (depending on the application and flow medium) to ensure a firm seal between the valve and the flange connection.

Lug type butterfly valves are usually made of metals such as ductile iron or stainless steel carbon steel. They feature bolt holes in the valve for flange mounting, usually 8 holes for bolting. Lug butterfly valves of the same size weigh more than wafer butterfly valves and cost a little more.

The main difference is the different ways of installing the link pipe. Wafer butterfly valve must use special butterfly valve flange. Butterfly valve flange in the installation must ensure that the flange surface and sealing rubber centred, screws evenly tightened, the sealing surface must fit intact; if there is a screw tightening strength is not uniform there will be a rubber bulge stuck butterfly plate, or the top of the butterfly plate caused by the valve stem at the leakage.Lug Butterfly Valve Installation Methods will be the bolts through the pipeline flange, and then tighten it to the lugged butterfly valve corresponding to the bolt holes, you need to uniformly tighten it. Lug type bolts are shorter and do not need to go through the whole valve body. It avoids the risk of easy leakage due to the large creep generated by the relatively long valve bolts.lug type butterfly valves are suitable for end-of-line service, but it is recommended that blind flanges are always used. lug type butterfly valves are compatible with pneumatic or electric actuators.

Manual, Handwheel with gear train, pneumatic, electric, hydraulic and so on. Handlever butterfly valve cost the lowest suitable for less than 300 mm calibre butterfly valve, if greater than 300 mm torque is too large manual operation is difficult mainly used for water treatment, Gearbox butterfly valve used in the torque of the valve, easy to operate affordable, pneumatic butterfly valve and electric butterfly valve belongs to the automatic control of the valve, without manual operation, the use of air or electricity as a source of power, you can drive the valve to work, mostly used in the Pneumatic butterfly valves and electric butterfly valves are automatic control valves, which do not require manual operation and can be operated by air or electricity as power source to drive the valve to work. Hydraulic butterfly valve is mainly composed of hydraulic station, speed pipe actuator, PLC intelligent electrical control box, special trip feedback device and so on. It is widely used in blast furnace gas pipeline system in metallurgical industry to prevent gas tempering in the pipeline. Used in the power industry for emergency shut-off valves in order to prevent a sudden drop in the load of the turbine from backfiring steam from the inhaler and each heater into the turbine, resulting in a nasty accident that destroys and damages the turbine blades. If dangerous operating conditions occur in the system, the emergency shut-off valve can be implemented within 0.5 seconds to achieve stable closure of the pipeline, effectively preventing the backflow of steam and condensate from the tail end of the steam engine and protecting the safety of the turbine. Hydraulic butterfly valves with the highest cost require a hydraulic station.

Butterfly valve and other mechanical products, as well as the need for maintenance. Maintenance work done well, can significantly extend the service life

1. Connection coated with lubricant: valve stem threads, often friction with the nut, to be coated with a little bit of yellow dry oil, molybdenum disulfide or graphite powder, to play a smoothing sensation. Infrequent use of the valve, but also to migrate the handwheel on a regular basis, the stem threads to increase the lubricant, in order to prevent jamming. If the pneumatic ventilated butterfly valve machine to be moved, to increase the lubricant on the gearbox on time.

2.outdoor valve stem to add a protective sleeve: for outdoor pneumatic electric ventilated butterfly valve, to add a protective sleeve to the valve stem to prevent rain, snow, dust rust pollution.

3.keep parts intact: check and adhere to the pneumatic ventilation butterfly valve parts intact. If there is a solid nut of the handwheel is missing, to match, to cope with the untimely situation, otherwise it will grind round the upper part of the valve stem in four directions.

4.keep clean: to adhere to the pneumatic ventilation butterfly valve clean, valve stem, especially the threaded part, to often wipe, the smoothing agent to be soiled by dust to be replaced by a new one, due to the dust contains hard debris, easy to wear the threads and the outside of the valve stem will affect the service life.

5.shall not support heavy objects: pneumatic ventilation butterfly valve shall not support other heavy objects, do not stand on the pneumatic ventilation butterfly valve.

Purchase high-quality butterfly valve products, for butterfly valve service life is more protection!

One of the main advantages of valves is that they all look the same but function very differently, and this is the case wafer butterfly valves and lug butterfly valves. We at tfwvalve, one of the leading valve manufacturers in China, ensure that these facts are part of our valve designs. The valves we manufacture offer excellent functionality and comply with international standards such as CE certified valves, ISO9001, ACS certified valves in France and more. This is thanks to research and development by our team of experts. We have the perfect solution to meet your valve requirements.Contact us for a competitive quotation.

Company Name: Tianjin Tangfa Watts Valve Co., Ltd.

Contact Person: Mr. jack wang (General Manager)

+86 22 66224148

+86 22 25291233

RM8401-3,TIANHE TECHNICAL ZONE,BINHAI NEW AREA,TIANJIN CITY,CHINA