- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

English

News Center

The hard sealing material, which is typically metal, exhibits relatively poor sealing performance. The inability of soft sealing to meet the process requirements for some corrosive materials is a limitation that hard sealing can address. The two aforementioned sealing types can be employed in conjunction with one another. In terms of sealing performance, soft sealing is relatively superior, but hard sealing has also demonstrated an improvement in sealing performance to meet corresponding requirements.

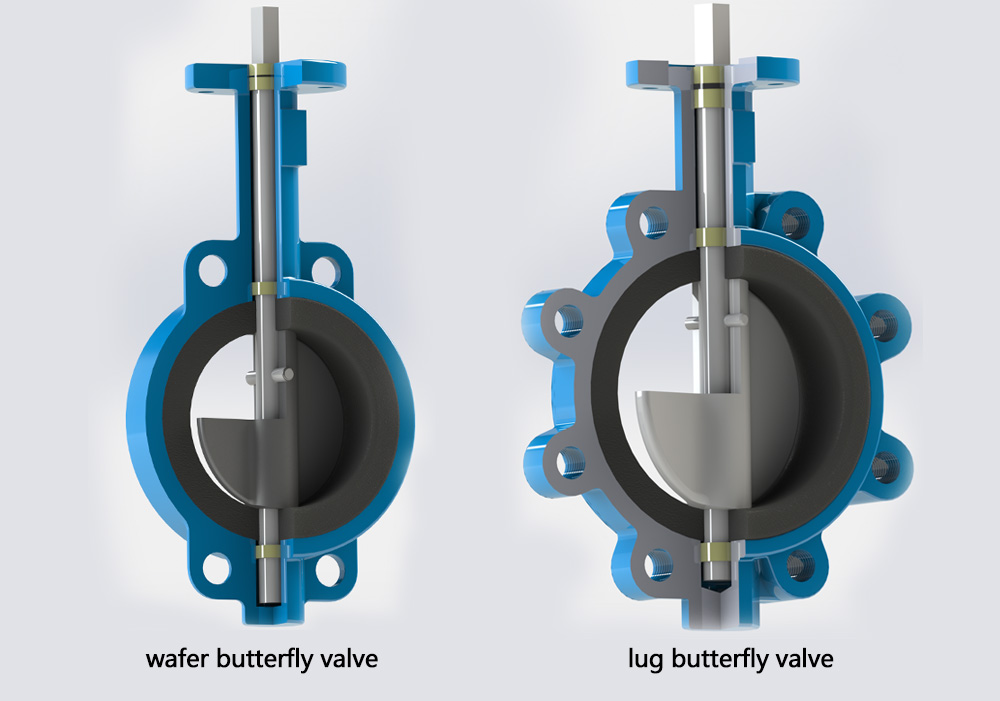

Amongst the plethora of industrial valves, the wafer-style butterfly valve is renowned for its distinctive design and effective fluid control capabilities. Its unique lamellar design comprises a fixed disc mounted on a rotating axis, which rotates to completely block the passage when the valve is cl

Find out the most suitable valve type for your industrial requirements and guarantee peak performance with routine maintenance.I. What is a butterfly valve?Butterfly valve can be opened and closed quickly by rotating only 90°, easy to operate, and at the same time the valve has good fluid control ch

In a Significant Leap for Water Safety Standards, Tianjin Tangfa Watts Valve Co., Ltd. Secures Recognition in the Global Market