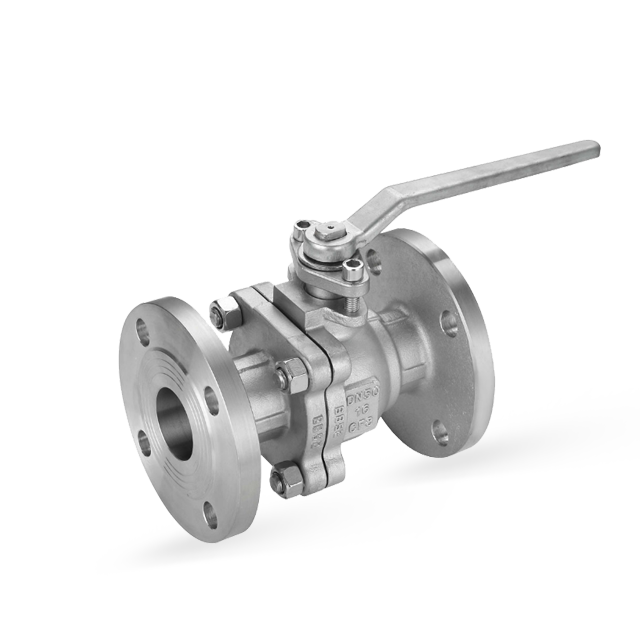

Globe valve working principle The closing principle of the shut-off valve is to rely on the pressure of the valve stem to make the sealing surface of the disc and the sealing surface of the valve seat closely fit to prevent the medium from flowing. The shut-off valve only allows the medium to flow in one direction and is directional when installed. Its structural length is greater than that of the gate valve, and the fluid resistance is large, and the sealing reliability is not strong during long-term operation. There are three types of globe valves: straight-through, right-angle and direct-flow oblique globe valves. Stop valve function The cut-off valve, also called the cut-off door, plays an important role in cutting off and throttling the medium in the pipeline. The globe valve is a very widely used valve. The reason why it is so popular is that the friction between the sealing surfaces during the opening and closing process is small, it is relatively durable, has a small opening height, is easy to manufacture, and is convenient to maintain. It is not only suitable for medium Low pressure, but also suitable for high pressure. Pressure test method In the strength test, the assembled valve is usually placed in the pressure test rack, the valve disc is opened, the medium is injected to the specified value, and the valve body and the valve cover are checked for sweat and leakage. The strength test can also be performed on a single piece. During the sealing test, the valve stem of the stop valve is in a vertical state, the valve flap is opened, and the medium is introduced from the bottom end of the valve flap to the specified value. Check the packing and gasket; after passing the test, close the valve flap and open the other end to check for leakage leak. If both the valve strength and tightness tests are to be done, the strength test can be done first, then the pressure is reduced to the specified value of the tightness test, and the packing and gaskets are checked; then the valve flap is closed and the outlet end is opened to check whether the sealing surface is leaking.  Ball valve working principle The ball valve is a valve that uses a sphere with a circular channel as an opening and closing part, and the sphere rotates with the valve stem to realize the opening and closing action. The opening and closing part of the ball valve is a sphere with holes, which rotates around the axis perpendicular to the passage, so as to achieve the purpose of opening and closing the passage. Ball valve action Ball valves are mainly used to open and close pipelines and equipment media, and are mainly used to quickly switch fluids. Because the degree of switching is not easy to adjust and control accurately, it is not suitable for flow adjustment. Pressure test method The strength test of the pneumatic ball valve should be carried out with the ball half open. Floating ball valve tightness test: Put the valve in a half-open state, introduce the test medium at one end, and close the other end; rotate the sphere several times, open the closed end to check when the valve is in the closed state, and check the sealing performance of the packing and gasket at the same time, there should be no leakage. Then introduce the test medium from the other end and repeat the above test. Sealing test of fixed ball valve: Before the test, rotate the sphere without load several times, the fixed ball valve is in the closed state, and the test medium is introduced from one end to the specified value; the pressure gauge is used to check the sealing performance of the introduction end, and the accuracy of the pressure gauge is 0.5 to 1 with the range of 1.5 times the test pressure. Within the specified time, there is no decompression phenomenon as qualified; then introduce the test medium from the other end, and repeat the above test. Then, put the valve in a half-open state, with both ends closed, and the inner cavity filled with medium. Check the packing and gasket under the test pressure, and there should be no leakage. The three-way ball valve shall be tested for tightness at each position.  Check valve working principle Check valve refers to the valve that automatically opens and closes the disc depending on the flow of the medium itself to prevent the medium from flowing back. It is also called check valve, one-way valve, reverse flow valve, and back pressure valve. This kind of valve works automatically. Under the action of the fluid pressure flowing in one direction, the valve flap opens; when the fluid flows in the opposite direction, the fluid pressure and the self-coincidence of the valve flap act on the valve seat, thereby cutting off the flow. Check valve function Check valve is a kind of automatic valve, its main function is to prevent the back flow of the medium, prevent the pump and drive motor from reversing, and discharge the container medium. The check valve can also be used to supply the auxiliary system whose pressure may rise above the system pressure. Check valves can be divided into swing check valves (rotating according to the center of gravity) and lift check valves (moving along the axis). Pressure test method Check valve test state: lift check valve disc axis is in a position perpendicular to the horizontal; swing check valve channel axis and disc axis are in a position approximately parallel to the horizontal line. During the strength test, the test medium is introduced from the inlet end to the specified value, and the other end is closed. It is qualified if there is no leakage in the valve body and bonnet. In the sealing test, the test medium is introduced from the outlet end, and the sealing surface is checked at the inlet end. No leakage at the packing and gasket is qualified. Recommended by valve manufacturers Fujian Huaguang Valve Factory has 20 years of production experience. Since its establishment, it has always adhered to the brand-oriented enterprise development goal and the establishment of a Chinese famous brand as the enterprise development goal. It attaches great importance to the implementation of quality management and has passed the quality system certification. The fluorine-lined valve series is at the leading level among similar domestic products.

|

|

|