- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

English

| Availability: | |

|---|---|

| Quantity: | |

TT,alibaba,paypal

5

Specifications:

Nominal pressue (MPa) | 1.0 | 1.6 | |

Nominal diameter(mm) | 50-1000 | 50-1000 | |

Test pressure | Shell | 1.5 | 2.4 |

(MPa) | Seal | 1.1 | 1.76 |

Applicable temperature | 150 | ||

Applicable medium | Fresh water, Sewage, Sea water, Air, Vapor, Food, Medicine, Oils, Acids, | ||

Operating mode | manual, worm gear, pneumatic, electric, etc. | ||

Standards:

Design & Manufacture | Flange Connection | Face to Face Dimension | Test & Inspection |

API 594 | DIN PN10/16/25 | API594 | API 598 |

Material:

| body | Cast Iron, Ductile Iron, Carbon Steel, Stainless Steel |

| Plate | Ductile Iron, Carbon Steel, Stainless Steel |

| Spring | Stainless Steel |

| Hinge Pin | Stainless Steel |

| Plug | carbon steel |

| Body Bearing | PTFE |

| Spring Bearing | PTFE |

| Stop Pin | Stainless Steel |

| Eye Bolt | Carbon Steel |

| Body Seat | NBR, EPDM, Viton, Neoprene |

Application:

Chemicals, air, water, steam, oil, acids, salts ect

Features:

1. Small in size, light in weight, compact in structure,easy in maintenance.

2. Two torsion springs are used excreting on each of the pair valve plates,which close the plates quickly

And automatically.

3. The quick-close action prevents the medium from flowing back and eliminates water hammer effect.

4. Short body structure length and good rigidity.

5. This valve is tightly sealed, without leakage under the pressure water test.

6. Safe and reliable in operation,high interference-resistance.

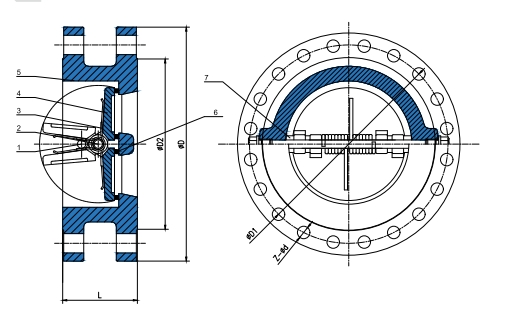

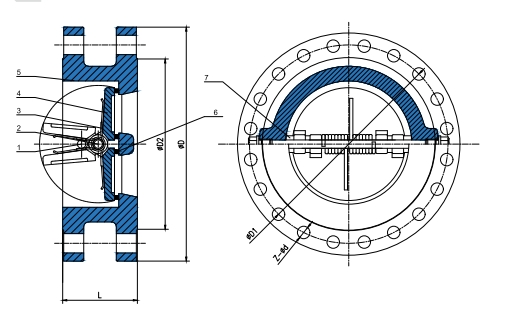

STANDARD MATERIALS OF MAIN PARTS

| ITEM | PART NAME | MATERIAL |

|---|---|---|

| 1 | STOP PIN | Ss304 |

| 2 | HINGLE PIN | Ss304 |

| 3 | SPRING | Ss304 |

| 4 | PLATE | DI |

| 5 | BODY | CI |

| 6 | SEAT | EPDM |

| 7 | BEARING | PTFE |

DIMENSIONS: (mm)

| SIZE (inches) | DN | L | PN10 | PN16 | ||||

|---|---|---|---|---|---|---|---|---|

| D | D1 | D2 | Z-d | D | D1 | |||

| 2 | 50 | 43 | 165 | 125 | 99 | 4-19 | 165 | 125 |

| 2.5 | 65 | 46 | 185 | 145 | 118 | 4-19 | 185 | 145 |

| 3 | 80 | 64 | 200 | 160 | 132 | 8-19 | 200 | 160 |

| 4 | 100 | 64 | 220 | 180 | 156 | 8-19 | 220 | 180 |

| 5 | 125 | 70 | 250 | 210 | 184 | 8-19 | 250 | 210 |

| 6 | 150 | 76 | 285 | 240 | 211 | 8-23 | 285 | 240 |

| 8 | 200 | 89 | 340 | 295 | 266 | 12-23 | 340 | 295 |

| 10 | 250 | 114 | 405 | 355 | 319 | 12-23 | 405 | 355 |

| 12 | 300 | 114 | 460 | 410 | 370 | 12-28 | 460 | 410 |

| 14 | 350 | 127 | 520 | 470 | 429 | 16-28 | 520 | 470 |

| 16 | 400 | 140 | 580 | 525 | 480 | 16-31 | 580 | 525 |

| 18 | 450 | 152 | 640 | 585 | 548 | 20-31 | 640 | 585 |

| 20 | 500 | 152 | 715 | 650 | 609 | 20-34 | 715 | 650 |

| 24 | 600 | 178 | 840 | 770 | 720 | 20-37 | 840 | 770 |

| 28 | 700 | 229 | 910 | 840 | 794 | 24-37 | 910 | 840 |

| 32 | 800 | 241 | 1025 | 950 | 901 | 24-41 | 1025 | 950 |

| 36 | 900 | 241 | 1125 | 1050 | 1001 | 28-41 | 1125 | 1050 |

| 40 | 1000 | 300 | 1255 | 1160 | 1112 | 28-44 | 1255 | 1170 |

A check valve is a mechanical valve that allows fluid (liquid or gas) to flow in only one direction. It automatically prevents backflow or reverse flow of the fluid.

The main purpose of a check valve is to ensure that the fluid can only travel in the desired direction within a piping system or machine. It operates automatically by opening to permit forward flow and closing to prevent reverse flow.

A flange check valve is a type of check valve that has flanged ends to allow connection to pipes or other equipment using bolt holes on the flanges.

The key features of a flange check valve are:

Flanged ends: The valve body has flanges at both the inlet and outlet ends. These flanges have bolt holes arranged in a circular pattern to allow bolting and connecting to mating flanges on pipes or equipment.

Flow direction control: Like other check valves, it allows flow in one direction but prevents reverse flow in the opposite direction.

Valve mechanism: It can have different types of internal valve mechanisms like a swing disc, lift disc, ball, or spring-loaded components to control the flow direction.

Flange check valves are commonly used in piping systems that require frequent disassembly for maintenance or inspection, as the flanged ends allow easy removal and re-installation of the valve. They are available in various materials like steel, stainless steel, cast iron, etc. to suit different application requirements.

The flanged design allows flange check valves to be installed between piping flanges using gaskets and bolts, making them a convenient choice in many industrial fluid handling systems like water supply, chemical processing, oil and gas, and others.

ASME B16.5 - Pipe Flanges and Flanged Fittings This specifies dimensions, pressure-temperature ratings, facings, materials, etc. for pipe flanges including those used on flange check valves.

ASME B16.34 - Valves - Flanged, Threaded, and Welding End

This covers design, materials, testing, marking and documentation requirements specifically for flanged valves like flange check valves.

API 598 - Valve Inspection and Testing Published by the American Petroleum Institute (API), it defines the inspection and testing criteria for valves including flanged check valves used in the oil and gas industry.

API 6D - Specification for Pipeline and Piping Valves Another API standard providing requirements for design, manufacturing, testing and documentation of pipeline valves like flanged check valves.

BS EN 12334 - Industrial Valves - Cast Iron Check Valves This British/European standard is specifically for cast iron check valves with flanged or other end connections.

ISO 16136 - Industrial Valves - Butterfly Valves of Metallic Materials While focused on butterfly valves, it also covers some aspects related to flanged check valves.

The selection of the applicable standard depends on the industry, piping material, pressure/temperature ratings, and the specific requirements of the installation. Manufacturer's standards may also be referenced in some cases.

Specifications:

Nominal pressue (MPa) | 1.0 | 1.6 | |

Nominal diameter(mm) | 50-1000 | 50-1000 | |

Test pressure | Shell | 1.5 | 2.4 |

(MPa) | Seal | 1.1 | 1.76 |

Applicable temperature | 150 | ||

Applicable medium | Fresh water, Sewage, Sea water, Air, Vapor, Food, Medicine, Oils, Acids, | ||

Operating mode | manual, worm gear, pneumatic, electric, etc. | ||

Standards:

Design & Manufacture | Flange Connection | Face to Face Dimension | Test & Inspection |

API 594 | DIN PN10/16/25 | API594 | API 598 |

Material:

| body | Cast Iron, Ductile Iron, Carbon Steel, Stainless Steel |

| Plate | Ductile Iron, Carbon Steel, Stainless Steel |

| Spring | Stainless Steel |

| Hinge Pin | Stainless Steel |

| Plug | carbon steel |

| Body Bearing | PTFE |

| Spring Bearing | PTFE |

| Stop Pin | Stainless Steel |

| Eye Bolt | Carbon Steel |

| Body Seat | NBR, EPDM, Viton, Neoprene |

Application:

Chemicals, air, water, steam, oil, acids, salts ect

Features:

1. Small in size, light in weight, compact in structure,easy in maintenance.

2. Two torsion springs are used excreting on each of the pair valve plates,which close the plates quickly

And automatically.

3. The quick-close action prevents the medium from flowing back and eliminates water hammer effect.

4. Short body structure length and good rigidity.

5. This valve is tightly sealed, without leakage under the pressure water test.

6. Safe and reliable in operation,high interference-resistance.

STANDARD MATERIALS OF MAIN PARTS

| ITEM | PART NAME | MATERIAL |

|---|---|---|

| 1 | STOP PIN | Ss304 |

| 2 | HINGLE PIN | Ss304 |

| 3 | SPRING | Ss304 |

| 4 | PLATE | DI |

| 5 | BODY | CI |

| 6 | SEAT | EPDM |

| 7 | BEARING | PTFE |

DIMENSIONS: (mm)

| SIZE (inches) | DN | L | PN10 | PN16 | ||||

|---|---|---|---|---|---|---|---|---|

| D | D1 | D2 | Z-d | D | D1 | |||

| 2 | 50 | 43 | 165 | 125 | 99 | 4-19 | 165 | 125 |

| 2.5 | 65 | 46 | 185 | 145 | 118 | 4-19 | 185 | 145 |

| 3 | 80 | 64 | 200 | 160 | 132 | 8-19 | 200 | 160 |

| 4 | 100 | 64 | 220 | 180 | 156 | 8-19 | 220 | 180 |

| 5 | 125 | 70 | 250 | 210 | 184 | 8-19 | 250 | 210 |

| 6 | 150 | 76 | 285 | 240 | 211 | 8-23 | 285 | 240 |

| 8 | 200 | 89 | 340 | 295 | 266 | 12-23 | 340 | 295 |

| 10 | 250 | 114 | 405 | 355 | 319 | 12-23 | 405 | 355 |

| 12 | 300 | 114 | 460 | 410 | 370 | 12-28 | 460 | 410 |

| 14 | 350 | 127 | 520 | 470 | 429 | 16-28 | 520 | 470 |

| 16 | 400 | 140 | 580 | 525 | 480 | 16-31 | 580 | 525 |

| 18 | 450 | 152 | 640 | 585 | 548 | 20-31 | 640 | 585 |

| 20 | 500 | 152 | 715 | 650 | 609 | 20-34 | 715 | 650 |

| 24 | 600 | 178 | 840 | 770 | 720 | 20-37 | 840 | 770 |

| 28 | 700 | 229 | 910 | 840 | 794 | 24-37 | 910 | 840 |

| 32 | 800 | 241 | 1025 | 950 | 901 | 24-41 | 1025 | 950 |

| 36 | 900 | 241 | 1125 | 1050 | 1001 | 28-41 | 1125 | 1050 |

| 40 | 1000 | 300 | 1255 | 1160 | 1112 | 28-44 | 1255 | 1170 |

A check valve is a mechanical valve that allows fluid (liquid or gas) to flow in only one direction. It automatically prevents backflow or reverse flow of the fluid.

The main purpose of a check valve is to ensure that the fluid can only travel in the desired direction within a piping system or machine. It operates automatically by opening to permit forward flow and closing to prevent reverse flow.

A flange check valve is a type of check valve that has flanged ends to allow connection to pipes or other equipment using bolt holes on the flanges.

The key features of a flange check valve are:

Flanged ends: The valve body has flanges at both the inlet and outlet ends. These flanges have bolt holes arranged in a circular pattern to allow bolting and connecting to mating flanges on pipes or equipment.

Flow direction control: Like other check valves, it allows flow in one direction but prevents reverse flow in the opposite direction.

Valve mechanism: It can have different types of internal valve mechanisms like a swing disc, lift disc, ball, or spring-loaded components to control the flow direction.

Flange check valves are commonly used in piping systems that require frequent disassembly for maintenance or inspection, as the flanged ends allow easy removal and re-installation of the valve. They are available in various materials like steel, stainless steel, cast iron, etc. to suit different application requirements.

The flanged design allows flange check valves to be installed between piping flanges using gaskets and bolts, making them a convenient choice in many industrial fluid handling systems like water supply, chemical processing, oil and gas, and others.

ASME B16.5 - Pipe Flanges and Flanged Fittings This specifies dimensions, pressure-temperature ratings, facings, materials, etc. for pipe flanges including those used on flange check valves.

ASME B16.34 - Valves - Flanged, Threaded, and Welding End

This covers design, materials, testing, marking and documentation requirements specifically for flanged valves like flange check valves.

API 598 - Valve Inspection and Testing Published by the American Petroleum Institute (API), it defines the inspection and testing criteria for valves including flanged check valves used in the oil and gas industry.

API 6D - Specification for Pipeline and Piping Valves Another API standard providing requirements for design, manufacturing, testing and documentation of pipeline valves like flanged check valves.

BS EN 12334 - Industrial Valves - Cast Iron Check Valves This British/European standard is specifically for cast iron check valves with flanged or other end connections.

ISO 16136 - Industrial Valves - Butterfly Valves of Metallic Materials While focused on butterfly valves, it also covers some aspects related to flanged check valves.

The selection of the applicable standard depends on the industry, piping material, pressure/temperature ratings, and the specific requirements of the installation. Manufacturer's standards may also be referenced in some cases.

Company Name: Tianjin Tangfa Watts Valve Co., Ltd.

Contact Person: Mr. jack wang (General Manager)

+86 22 66224148

+86 22 25291233

RM8401-3,TIANHE TECHNICAL ZONE,BINHAI NEW AREA,TIANJIN CITY,CHINA