- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

English

In industrial systems, valves are the core equipment for controlling fluid flow and pressure. The valve bonnet, as an important part of the valve, directly affects the system's operational efficiency and safety through its selection and design.

READ MORE

This article takes butterfly valves and globe valves as examples to explore in detail how to choose the appropriate valve type based on different operating conditions, highlighting their respective advantages, disadvantages, and application scenarios.

READ MORE

In industrial production and daily life, butterfly valves play a crucial role as key devices for controlling fluid flow. The torque of a butterfly valve is an important performance indicator, directly impacting ease of operation, reliability, and lifespan. A deeper understanding of butterfly valve torque is essential for improving operational efficiency.

READ MORE

Swing check valves are widely used due to their simple design and effectiveness in many applications. Their bodies are similar to those of globe valves, but most check valves lack a valve stem handle or handwheel. The main components of a swing check valve include a replaceable valve seat, valve disc, pivot arm, and bonnet. The bonnet is the top part of the valve body and can be removed for easy maintenance of the valve disc.

READ MORE

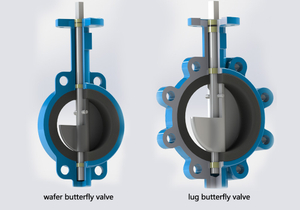

Find out the most suitable valve type for your industrial requirements and guarantee peak performance with routine maintenance.I. What is a butterfly valve?Butterfly valve can be opened and closed quickly by rotating only 90°, easy to operate, and at the same time the valve has good fluid control ch

READ MORE